The EZ Ballast system (“E-Z” = “ea-sy”) was awarded with a silver medal at Agritechnica 2015.

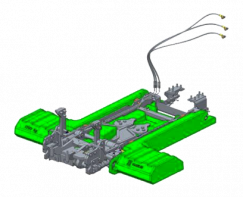

It is the first flexible ballast system available in the market, using the undercarriage of the tractor for ballasting purposes. The system opens new ballasting possibilities for the farmers.

Benefits of EZ ballast:

✔ Ideal for farmers or contractors running versatile applications, switching frequently from field to road applications and requiring quick and easy changes of ballast

✔ Bringing the flexibility in running simultaneously front and rear implement combinations requiring ballast in the field

✔ No weight transfer like with a front or rear wheel weight. The system is designed to maintain the recommended weight split of the tractor

✔ Allows the farmer to optimize the performance of the tractor within few seconds only, without leaving the cab of the tractor

✔ Releasing the ballast save transport fuel cost and increase the payload on the road

✔ Adding the correct amount of ballast increase the productivity and reduce operating cost

Operations

Due to the high grower demand for more flexible ballasting solutions, John Deere invented in 2015 the EZ ballast system and LAFORGE developed it.

This exclusive system allows the operator to add and remove 1700 Kg (3,750 lb) weight within a minute. In addition, the driver does not need to leave the cab to add or remove the weight.

These are key benefits for those running versatile applications requiring changing the ballast often. If required, the farmer can even combine the EZ ballast with front and rear wheel weights to ballast the tractor to a very low power to weight ratio for heavy draft applications.

The system is controlled out of the cab via an additional control panel installed on the CommandARM.

Compatibility

- Drawbars and trailer hitches

- Sway blocks and stabilizer options

- LAFORGE and Deere Premium front hitch

- Pick-up hitch

- With all 7R Series Tractors down to model year 2011